Matt Compound

A kind of Matt Masterbatch or Compound special for matt film.

Using Matt Masterbatch in producing packaging polymeric films based on PE, PET, and PP, increases surface coating, smoothness, uniformity and quality. In addition, this Masterbatch can help producing wide variety of films with high or low thicknesses according to the screw extruder speed. Anti-oxidants, anti-block, and titanium dioxide can be used as additives in production process as well. The usage amount of this Masterbatch (5%-15%) can be changed according to the type of polymer.

Matt Compound can be used 100% and can be completely replaced instead of the original polymer .

BOPP/BOPET/BOPE/CPP/ 3-5 layer films

Matt is used in below applications:

- Packaging films and thin sheets based on PP, PET, and PE polymers

- Diaper and pad sheet

SUMMARY:

A kind of matt masterbatch or compound special for matt film.

Physical Properties

|

Index |

Value |

Unit |

Test Standard |

|

MFI (230 0C . 2.16KG) |

2 - 3 |

g/10min |

DIN53735 |

|

Shape |

White and opacity cylindrical particle |

……. |

…….. |

|

Density |

0.91 – 0.93 |

g/cm3 |

DIN53479 |

|

Volatile content (90 0C, 3hrs) |

0.16 |

% |

DW |

Our matt masterbatch or compound can be used in the production of matte film. We suggest adopt lower extrusion temperature and lower longitudinal stretching rate. Increasing the temperature of the chill roller also can reduce the luster effect and running high speed film.

ADVANTAGES:

Increase the capacity effectively

Reduce the educt from Die – head effectively

Reduce the luster effect

RECOMMENDED Usage:

100% As a Compound

5 to 15% As a Masterbatch

In order to have the ideal matte effect:

12-15 microns film, the minimum thickness of matte layer is more than H2 microns.

More than 15 microns film, the minimum thickness of matte layer is more than 3 microns.

PACKING:

LDPE 25KG Bags or 1MT jumbo Bags.

SUPER Matt

Technical Information:

Physical Properties

|

Brightness GR |

93% +/-0.5% |

|

Whiteness @ 460 Nano Microns – Photo-spectrometer |

90% +/-0.5% |

|

L |

98% |

|

a |

+0.05 |

|

B |

-0.12 |

|

Ph Extract |

8 |

|

Bulk Density gms/ltr |

350 to 400 |

|

Contrast Ratio % |

92 - 95 |

|

Residue on 500 # |

0.005% Max |

|

Volatile Matter |

0.05% |

|

Walter Demand |

100 ML – 120 ML /100Gms |

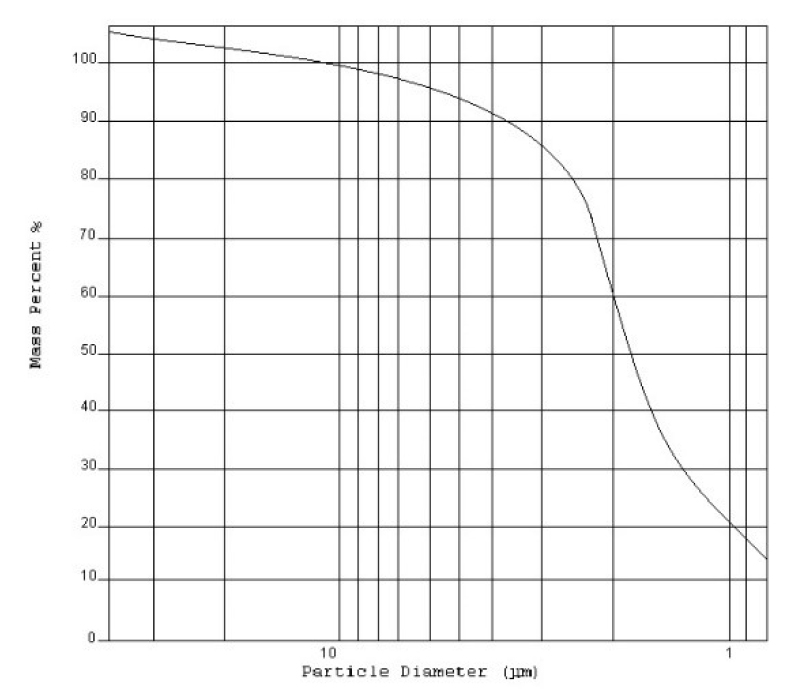

Particle Size Analysis

|

D-98 |

10.0 μ |

|

D-50 |

1.89 μ |

Benefits of Using SUPER Matt

High Thermal Conductivity – SUPER Matt has a higher Thermal Conductivity than the copolymer it transfer heat in much efficient manner, which in turns helps in decreasing the production time.

Matting Agent – Addition of SUPER Matt to the polymer mix will reduce the surface gloss and increase the mattness of the product.

Increase the Barrier Effect –SUPER Matt has better coverage area which reduces the transfer of water vapor and oxygen particles to travel through the polymer.

Rigidity at Higher Temperature – SUPER Matt has a very efficient in Deflection of Temperature and thus maintaining the rigidity of the polymer compound at high temperature.

STORAGE:

Copyright © 2020, Sirjan industrial manufacturing complex Corporation. Sirjan industrial manufacturing complex makes no representations, guarantees , or warranties of any kind with respect to the information contained in this document about its accuracy, suitability for particular applications, or the results obtained or obtainable using the information. Some of the information arises from laboratory work with small-scale equipment which may not provide a reliable indication of performance or properties obtained or obtainable on larger-scale equipment. Values reported as "typical" or stated without a range do not state minimum or maximum properties; consult your sales representative for property ranges and min/max specification. Processing condition can cause material properties to shift from the values stated in the information. Sirjan industrial manufacturing complex makes no warranties or guarantees respecting suitability of Sirjan industrial manufacturing complex's products or the information for your process or end-use application. You have the responsibility to conduct full-scale end-product performance tasting to determine suitability in your application, and you assume all risk and liability arising from your use of the information and/or use or handling of any product. Sirjan industrial manufacturing complex makes no warranties, express or implied, including, but not limited warranties of merchantability and fitness for a particular purpose, either with respect to the information or products reflected by the information. This data sheet shall NOT operate as permission, recommendation, or inducement to practice any patented invention without permission of the patent owner.